PFG-800 high quality CE pressure cooker fried chicken/pressure fryer/chicken fryer kfc

Why Choose A Pressure Fryer?

Pressure-fried chicken, often associated with fast-food chains like KFC, is prepared using a pressure fryer, which cooks the chicken quickly under high pressure and temperature. Now, let's talk about the top five benefits of pressure frying:

1. Faster Cook Times.

One of the top benefits of switching to pressure frying is how much shorter the cook times are. Frying in a pressurized environment leads to faster cooking times at a lower oil temperature than traditional open frying. This allows our customers to increase their overall production more than a conventional fryer, so they can cook faster and serve even more people in the same amount of time.

2. More Menu Possibilities.

PFE/PFG series of MJG pressure fryers not only possess the functions of traditional fryers but also come equipped with various intelligent modes. Users can select the appropriate mode based on different foods, ensuring the best frying effect for each type of food.

3. Better Food Quality.

With a pressure fryer, you can achieve consistent and even frying results quickly. The design allows for efficient heat transfer, ensuring that your food cooks evenly every time. This efficiency can help streamline your cooking process, saving you time and energy in the kitchen.

4. Cleaner Cooking Method.

With a pressure frying, all that oil-burdened steam is captured and exhausted into a hood above. This reduces greasy film and odors from building up in the surrounding area.

5. Consistently Great Taste.

MJG fryers use an accurate temperature control system with ±1℃. This system provide customers with precise, consistent taste and ensuring optimal frying results with minimal energy consumption. This not only guarantees the taste and quality of the food but also significantly extends the oil's lifespan. For restaurants that need to fry large amounts of food daily, this is a substantial economic advantage.

Electric & Gas chicken pressure fryer

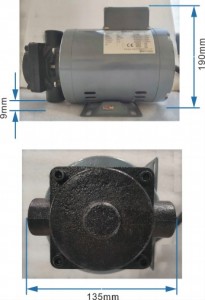

The thermostat, mounted on the elements, ensures precise temperature readings. The thermostat system minimizes temperature overshoot maximizing oil life.

Gas fryer for Burner (firerow) with 24pcs nozzles

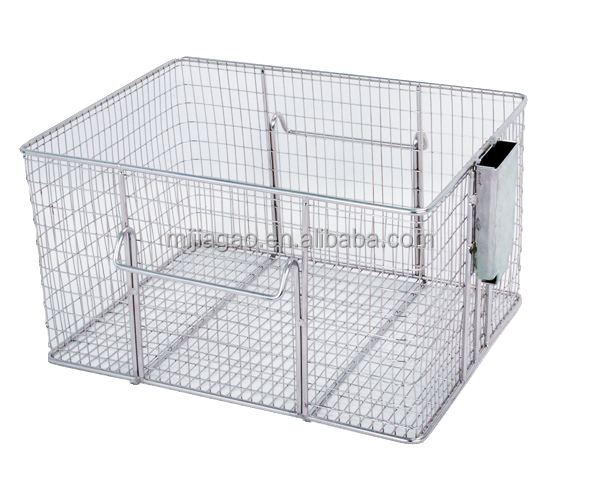

The large cold zone help collect and remove sediment from the frypot to safeguard oil quality and support routine cleaning. A rear flush feature moves sediment to the front drain valve for easy and thorough removal.

Electric Heating inner Cylinder

Gas Heating inner Cylinder

PFG/PFE-800 This series of pressure fryers have advanced electronic switching devices which pulse the amount of energy required to the electric elements in much smaller increments than traditional on/off electrical contactors or gas controls. The result: greater reliability and more precise temperature control. These models also have an insulated frypot which can reduce standby energy consumption by an additional 10%. It's can ensures pinpoint accuracy of oil temperature and adjusts cooking time for consistent high-quality production.

▶ All stainless steel body, easy to clean and wipe, with long service life.

▶ Aluminum lid, rugged and lightweight, easy to open and close.

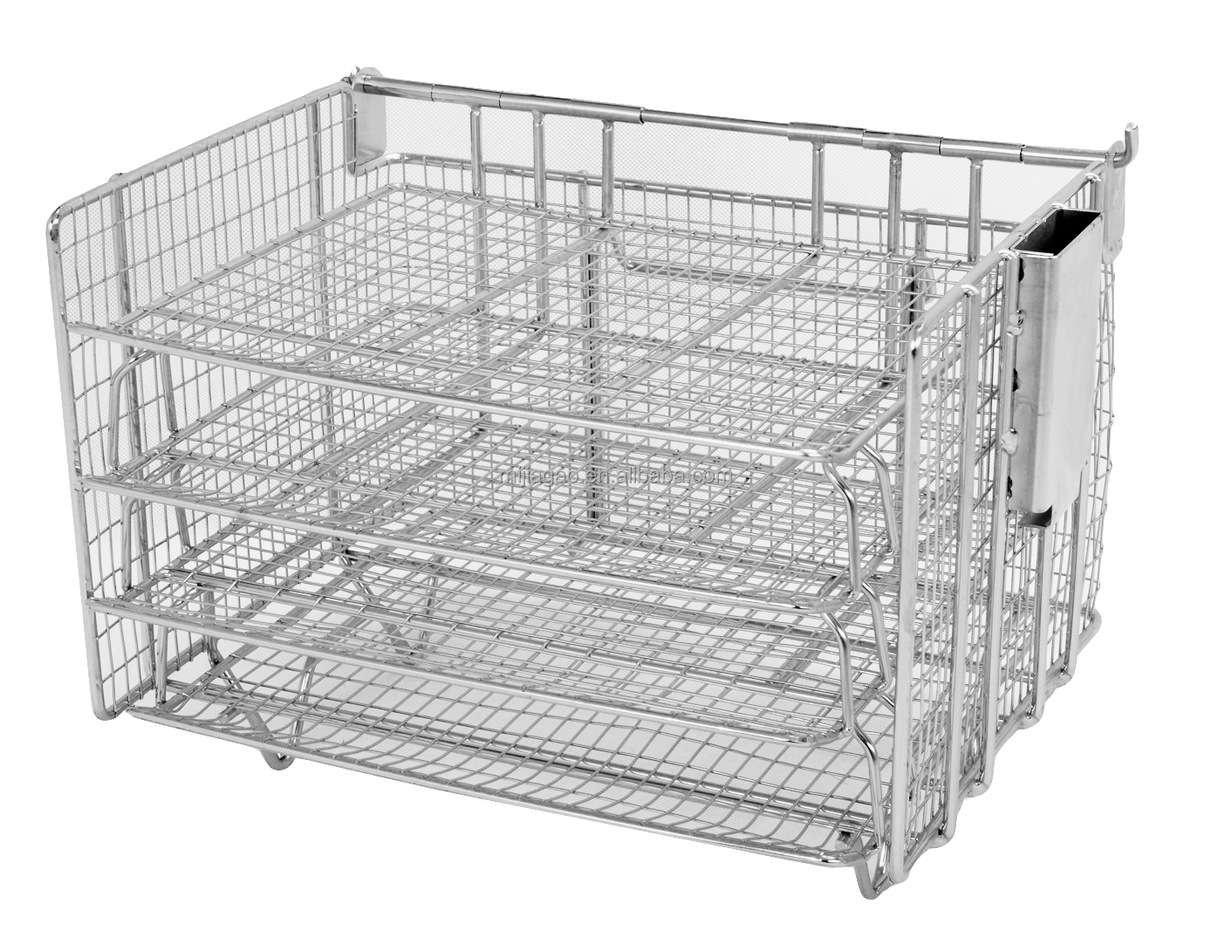

▶ Built-in automatic oil filter system, easy to use, efficient and energy-saving.

▶ The four casters have large capacity and are equipped with brake function, which is easy to move and position.

▶ Digital display control panel is more accurate and beautiful.

▶ The machine is equipped with 10-0 storage keys for 10 categories of food frying.

▶ Set the automatic exhaust after the time is up, and give an alarm to remind.

▶ Each product key can set 10 heating modes.

▶ Oil filter reminder and oil change reminder can be set.

▶ Switch to degrees Fahrenheit.

▶ Preheating time can be set.

▶ The cleaning time, idle mode and oil melting mode can be set.

▶ Pressure mode can be set on /off while at work.

| Specified Voltage | 3N~380V/50Hz-60Hz or 3N~220V/50Hz-60Hz |

| Energy | LPG or Natural Gas(Single phase 220V/50Hz-60Hz) |

| Temperature Range | 20-200 ℃ |

| Dimensions | 960 x 460 x 1230mm |

| Packing Size | 1030 x 510 x 1300mm |

| Capacity | 25 L |

| Net Weight | 135 kg |

| Gross Weight | 155 kg |

One of the key features that our customers love about MJG pressure fryers is the built-oil filtration systems. This automatic system helps extend oil life and reduces the maintenance required to keep your pressure fryer functioning. At MJG, we believe in making the most effective system possible, so this built-in oil filtration system comes standard on all our pressure fryers.

Superior Customer Support and After-Sales Service

Choosing a MJG fryer is not just about choosing a high-performance device but also about selecting a reliable partner. MJG provides comprehensive after-sales services, including installation guidance, usage training and on-line technical support. No matter what issues customers encounter during use, MJG's professional team can provide timely assistance to ensure the equipment is always in optimal condition.

1. Who are we?

We are based in Shanghai, China, start from 2018. We are the main kitchen and bakery equipment manufacturing vendor in China.We can provide a full set of kitchen equipment and bakery equipment.

2. How can we guarantee quality?

Always a pre-production sample before mass production; Every step in production is strictly supervised, and each machine must undergo at least 6 tests before leaving the factory.

3.What can you buy from us?

Open fryer, Deep fryer, counter top fryer, deck oven, rotary oven, dough mixer etc.

4. Why should you buy from us not from other suppliers?

All products are produced in our own factory, there is no middleman price difference between the factory and you. The absolute price advantage allow you to quickly occupy the market.

5. What services can we provide?

OEM service. Provide pre-sales technical and product consulation. Always after-sales technical guidance and spare parts service.

6. Payment method?

T/T in advance

7. Warranty?

One year

8. About shipment?

Usually within 5 working days after receiving the full payment.